The Role of Accurate Gas Analysis in Heat Treatment Applications

Heat treatment is a critical process across various industries, from metallurgy to aerospace and automotive manufacturing. As industries evolve and demands for more efficient, durable, and high-performing materials increase, the importance of precision in every step of production becomes paramount. In the realm of heat treatment, accurate gas analysis is a vital component that cannot be overlooked.

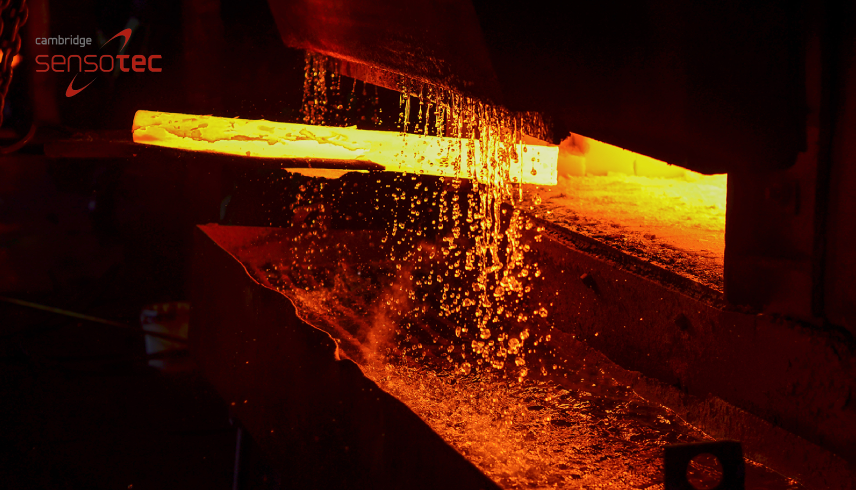

Understanding Heat Treatment

Heat treatment involves heating and cooling materials, usually metals and alloys, in a controlled manner to change their physical and mechanical properties without altering their shape. This process helps achieve various objectives, including enhancing strength, increasing ductility, improving toughness, and achieving desired hardness levels.

Gas Atmospheres and Their Significance

Different heat treatment processes employ various gases to create specific atmospheres that play pivotal roles in the outcomes. For instance, carburising uses a carbon-rich environment to infuse carbon into steel surfaces, while nitriding introduces nitrogen to achieve surface hardening.

An accurate understanding and control of the gas composition in these processes ensure the desired material properties. Any deviations can lead to material defects, compromised performance, or even failure in real-world applications.

The Need for Accurate Gas Analysis in Heat Treatment

1. Consistency and Reliability

Maintaining the consistent quality of treated materials is crucial. Accurate gas analysis ensures that the gas mixtures introduced during heat treatment are of the right composition. Even minor variations can result in inconsistent material properties, which can be detrimental in critical applications like aerospace or medical equipment.

2. Cost Efficiency

Using the wrong gas mixture or failing to maintain the desired atmosphere can lead to wastage of resources. Proper gas analysis prevents inefficiencies, ensures the use of only the necessary amount of gas, and achieves the desired outcome on the first attempt.

3. Safety

Certain gases can pose risks if they leak or mix with other gases unintentionally. Accurate monitoring and analysis of gases in heat treatment processes not only ensure the safety of the materials being treated but also protect the equipment and the professionals involved.

4. Innovation and Research

The UK is at the forefront of advanced materials research. As industries look for new materials with novel properties, accurate gas analysis becomes even more crucial. Only with precision can researchers experiment with different gas atmospheres and fine-tune the processes to achieve groundbreaking results.

Cambridge Sensotec: Leading the Way in Gas Analysis

Cambridge Sensotec has established itself as a leader in providing precise gas analysis solutions tailored for heat treatment applications. Our tools and devices are designed to offer reliability, accuracy, and efficiency, ensuring that industries get the best out of their processes.

Embracing the Future with Confidence

As we look to the future, the role of accurate gas analysis in heat treatment will only grow in importance. The challenges posed by evolving industries, stricter regulations, and the ever-growing demand for superior materials underscore the need for precision. With the right partners and tools in hand, businesses can confidently move forward, knowing that they are equipped to deliver the best to their customers.

Interested in enhancing the precision of your heat treatment processes? Discover how Cambridge Sensotec’s state-of-the-art gas analysis solutions can elevate your production standards. Contact us today to explore a partnership that promises accuracy, efficiency, and excellence.