Medical Gas Analysis

Within the medical sector, gases are extensively employed for therapeutic purposes. Ventilators and anaesthesia machines deliver gases directly to patients, assisting with respiration and pain management. Gases such as oxygen (O2), nitrous oxide (N2O) and medical air are indispensable in these life-saving applications. Additionally, gases are utilised in storage systems for preserving biological samples, cryogenic freezing of biological materials, and creating the optimal conditions for incubating cultures or specimens.

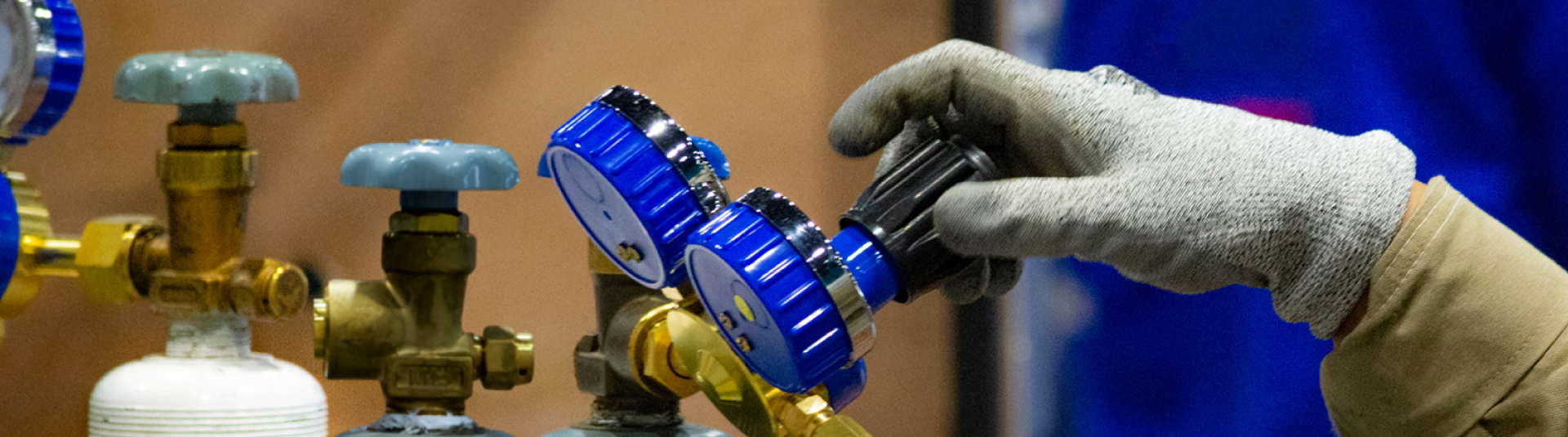

Gases used in hospitals are piped extensively around the buildings and there is constant risk that gas bottles and connection points are mixed up or plumbed incorrectly. Gas analysis of medical delivery systems is used to check for inadvertent cross contamination of, for example oxygen and nitrous oxide.

The pharmaceutical industry heavily relies on gases throughout the manufacturing process. In pharmaceutical production, gases are utilized for various applications, including solvent evaporation, drying, sterilization, and as part of chemical reactions. These gases ensure the quality, stability, and integrity of the pharmaceutical products and ingredients.

Most medicines and tables are supplied in nitrogen (N2) flushed packaging to improve the storage life and quality of the delivered product. Effervescent tablets need to be protected in dry gas with water removed, to prevent the tablet crumbing inside the packet. Most blister packs of tablets are nitrogen flushed and all these processes are tested with both on-line gas analysers and spot test equipment both destructively and not-destructively depending on the application.

Regulations within the medical and pharmaceutical industries demand that gases conform to stringent quality standards. Gas analysis is conducted to ensure compliance with these regulations, which include the identification and quantification of impurities and contaminants. By assessing the composition and purity of gases, manufacturers can verify that they meet the required specifications, ensuring patient safety, product efficacy, and adherence to regulatory guidelines.

Gas analysis plays a vital role in the medical and pharmaceutical industry, ensuring compliance with regulations, verifying gas purity, and assessing packaging integrity. The extensive use of gases in therapeutic applications, manufacturing processes, and storage systems necessitates meticulous gas analysis to maintain patient safety, product quality, and regulatory conformance.

Product Filters

Showing all 9 results

-

Rapidox 1100 Carbon Dioxide Gas Analyser

Rapidox 1100 Carbon Dioxide Gas AnalyserNumber of Gases 1 Sensor Option Internal -

Rapidox 1100 Carbon Monoxide Analyser

Rapidox 1100 Carbon Monoxide AnalyserNumber of Gases 1 Sensor Option Internal -

Rapidox 1100 Helium Analyser

Rapidox 1100 Helium AnalyserNumber of Gases 1 Sensor Option Internal -

Rapidox 1100 Methane Analyser

Rapidox 1100 Methane AnalyserNumber of Gases 1 Sensor Option Internal -

Rapidox 1100 Oxygen Analyser

Rapidox 1100 Oxygen AnalyserNumber of Gases 1 Sensor Option Internal -

Rapidox 3100 OEM-3

Rapidox 3100 OEM-3Number of Gases 1 Sensor Option Remote -

Rapidox 7100 Blue Hydrogen Analyser

Rapidox 7100 Blue Hydrogen AnalyserNumber of Gases Up to 7 Sensor Option Internal -

Rapidox 7100 Green Hydrogen Analyser

Rapidox 7100 Green Hydrogen AnalyserNumber of Gases Up to 7 Sensor Option Internal -

Rapidox 7100 Multigas Analyser

Rapidox 7100 Multigas AnalyserNumber of Gases Up to 7 Sensor Option Internal

Showing all 9 results