Rapidox 2100-OEM-RSB and DIN

Product Information

The Rapidox 2100-OEM-RSB range are special miniaturised 24V OEM versions of our existing high-performance zirconia oxygen (O2) analyser. The compact new design allows integration into the tightest of spaces with the exact same performance specs and features of our existing OEM analyser. The board is fitted with a robust cabled zirconia sensor, which is ideal for providing fast and accurate remote in-situ gas analysis over the full oxygen range 10-20ppm to 100% O2.

Read MoreProduct Information

Zirconia oxygen sensors are extremely rugged and particularly suitable for monitoring inert atmospheres and aggressive industrial applications directly within manufacturing processes such as metal 3D printers, soldering ovens and furnaces. High temperature (650°C) and vacuum applications are particularly suited to this model. The OEM has auxiliary sensor and temperature (type K) inputs for connecting additional sensors such as pressure, vacuum and dewpoint and can also monitor local ambient temperature and humidity conditions for improved stability.

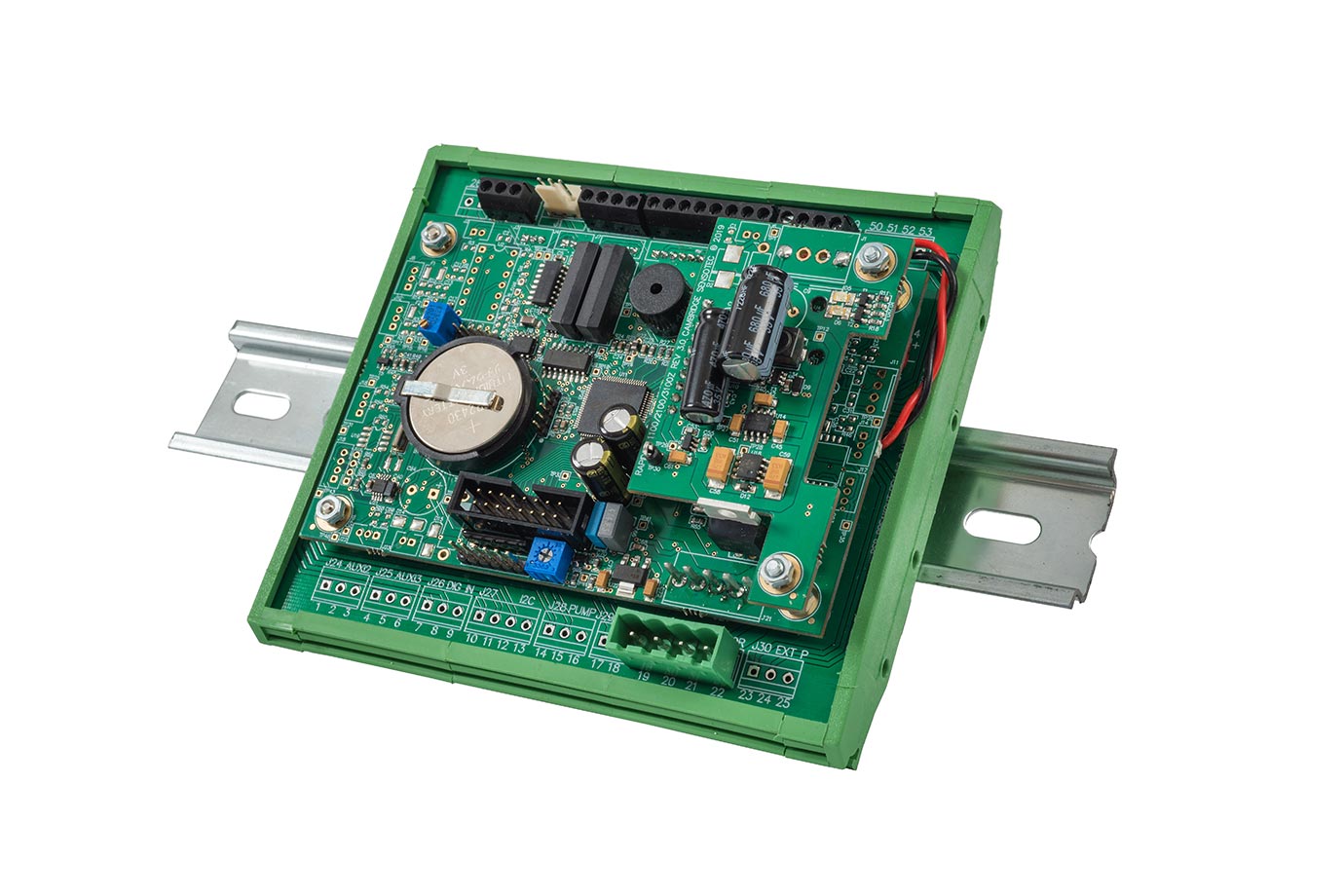

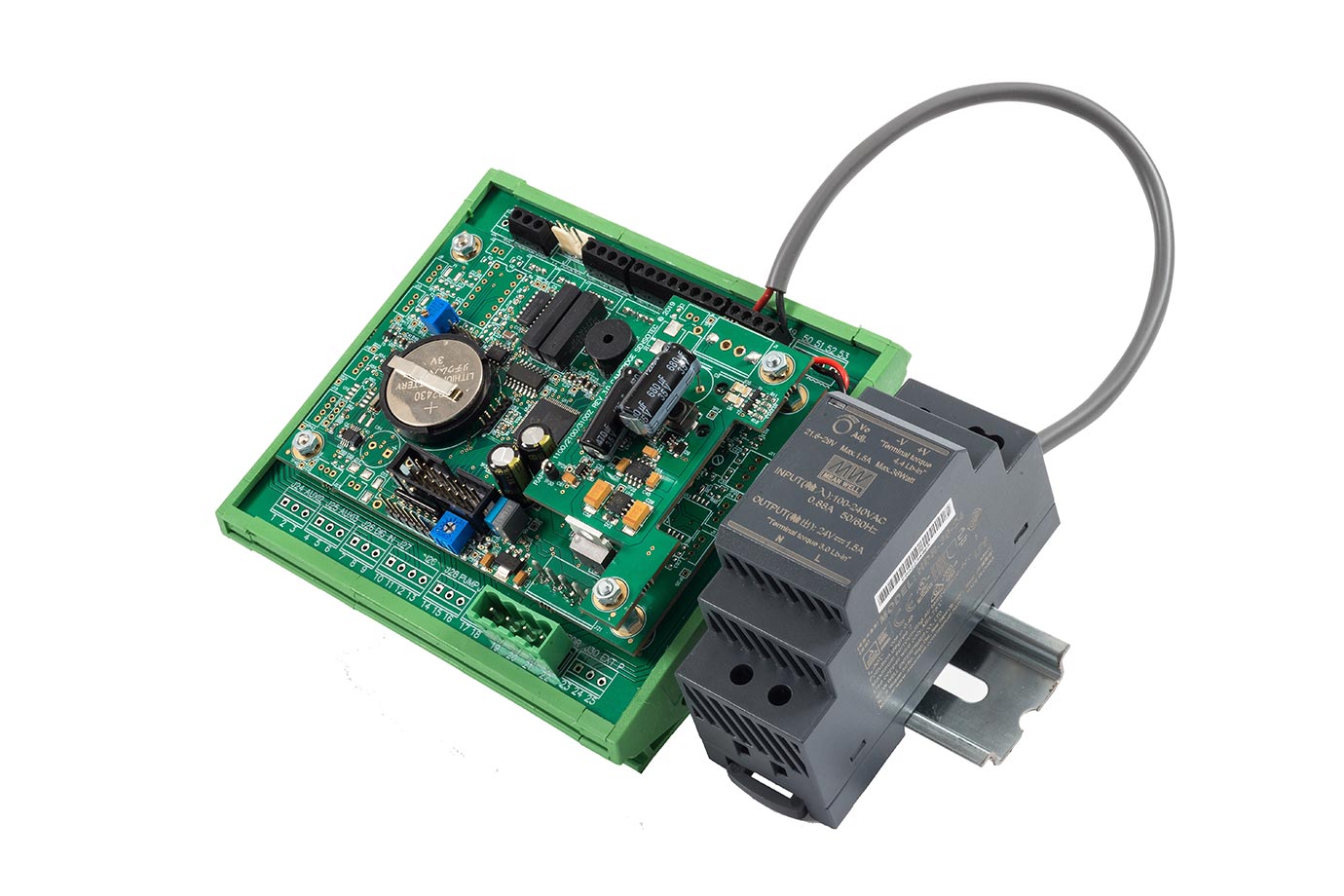

The analyser is supplied in four packages to meet the demands of any customer: a basic circuit board, a custom DIN rail version and a full metal DIN rail enclosure, with or without local display and keypad. The sensor cable can be made to any length up to 25m and there is a choice of sensor mounting options including aluminium and stainless manifolds as well as vacuum fittings (ISO-KF and CF). Fully programmable analogue (voltage and current) outputs and alarm relays as well as RS232 / RS485 digital signalling are standard. Rapidox digital communications protocol and Modbus-RTU is included as standard. The analyser is designed specifically for seamless integration into PLC systems. Finally, the Rapidox 2100-OEM-RSB complies with EMC Directive 2004 / 108 / EC. UL/ETL Certification Number: UL-61010-1.

Features

- Zirconia sensor supplied with bespoke cable

- Background gas calibration in both nitrogen and argon available for Zirconia sensors

- Miniature circuit board with DIN rail mount enclosure options

- Fast and accurate measurement of oxygen

- Pre-calibrated sensors for uninterrupted service

- Analogue and Digital outputs

- Data logging software

- Two programmable alarms

- Type K thermocouple option

- 24Vdc 20W power

- Complies with EMC Directive 2004 / 108 / EC. UL/ETL Certification Number: UL-61010-1

Product Resources

Product Specification

| Type | Measurement |

|---|---|

| O2 Sensor Range | 10-20ppm to 100% zirconia version. 10-26 extended range available on request |

| O2 Sensor Accuracy | ±1% of the actual measured oxygen content OR 0.5ppm (whichever is the greater) |

| Sample connections | Nipple or Swagelock |

| Warm-up time | 1-2 minutes at 20°C |

| Voltage outputs | 0-5V (0-10V on request) |

| Current outputs | 4-20mA |

| Digital outputs | RS232 / RS485 & Modbus RTU |

| Max Sample Gas Pressure | Up to 10 bar gauge (200bar burst pressure) |

| Max Sample Gas Temperature | 650°C |

| Ambient Operating Temperature | 5-35°C 0-95% RH non condensing |

| Din Rail Option | Board & 2 enclosed options |

| Calibration | Any two or three gases – Pre calibrated Sensors Available |

| Display | N/A |

| Supply Voltage | 24V VDC +/0.1V |

| Circuit Board Dimensions | 4.5″ x 3″ (114mm x 76mm) |

| Weight | <0.5kg in enclosure, OEM board 120g |